A Brief Discussion on the Differences between Industrial Control Computers and Integrated Industrial Control Computers

Time:2025-07-09What is an industrial computer?

Industrial computer is a computer used in industry. In industrial computers, system software can be installed, as well as application software and peripheral devices. Its role in industry is to input and output computer data to/from devices (i.e. input/output devices)

Convert data into control signals, or convert instruction signals into control instructions, and then control the operation or action of the corresponding equipment. According to the different control systems and controlled objects, industrial control computers can be divided into digital industrial control computers, embedded industrial control computers, and so on.

With the continuous development of computer technology, its application in various industries, especially in manufacturing, has far exceeded the performance of computer systems themselves. Industrial control computers have gradually become indispensable products in various industries, and their application fields are becoming more and more extensive. They are mainly used in industries such as electronic engineering, mechanical manufacturing, textile printing and dyeing, and packaging printing, playing a crucial role in various industries.

Characteristics of Industrial Control Computers

Industrial control computer refers to an industrial computer used to control computers and process computer instructions and data. It is based on various specialized equipment or integrated circuits, and integrates general processing and storage functions on a single chip or motherboard. It usually includes a CPU, memory module, hard drive, display controller (LCD), input/output interface board, etc.

Current situation of industrial computer market

Industrial control computer is an important component of embedded computers, which has a significant impact on data processing performance and stability. Industrial control computers have strong resistance to electromagnetic interference; Can withstand harsh working environments; Can achieve intelligence; Has strong error correction and fault tolerance capabilities; It can effectively avoid system damage caused by unauthorized behavior. Industrial control computers have strong data processing performance and stable and reliable characteristics, and have been widely used in industries such as petrochemicals, metallurgical machinery, power and electrical engineering, papermaking and printing, and transportation.

market demand

GODSPM industrial control computers have been widely used in the field of industrial control, and there is a strong demand for high reliability electronic products and computer systems in intelligent production of industrial enterprises. In the context of the intelligent era, industrial enterprises are developing towards automation, informatization, and networking. With the continuous application of computer technology in social production and life, there will be more new intelligent devices emerging and used in the future.

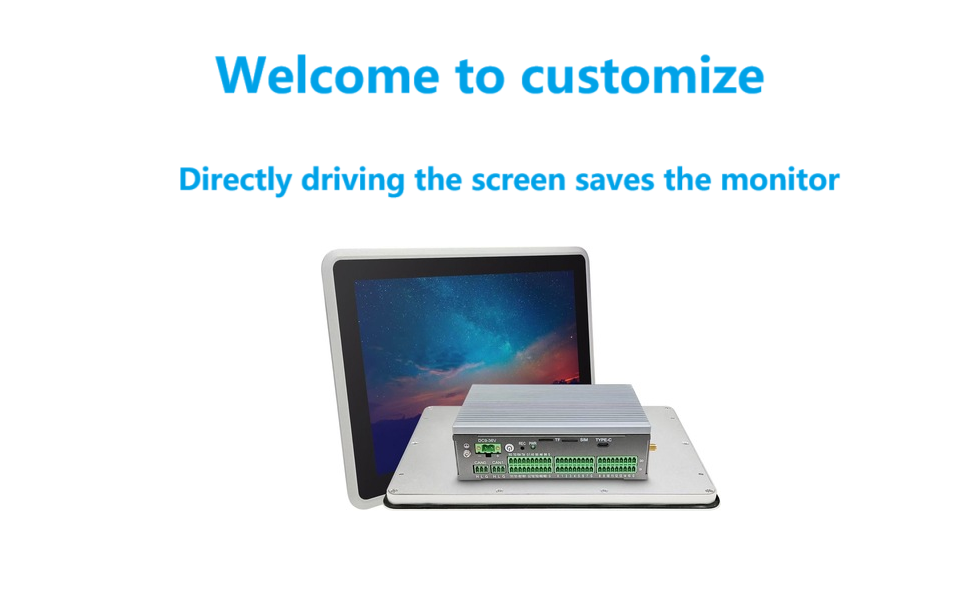

Industrial control all-in-one computer

Industrial control all-in-one computer is a new type of product that integrates PLC and display. It can be used as both industrial control equipment and data acquisition equipment. It integrates various functions of PC machines with industrial automation control systems, thus achieving an organic combination of the two.

Industrial control all-in-one computers are composed in a modular manner, which can meet the requirements of industrial automation, informatization, and networking applications. By combining advanced production processes with automation control technology, a high degree of integration of system software, hardware, and industrial control technology has been achieved. At the same time, it can improve production efficiency; Meet the needs of safety, reliability, energy conservation, and environmental protection; Enhance product reliability and stability to ensure application effectiveness; Reduce usage costs.

Product advantages

Industrial control all-in-one computer has powerful functions, stability and reliability, and strong scalability.

The industrial control all-in-one computer adopts a modular design, which has high reliability, high stability, and good scalability and configurability characteristics. It adopts a modular structure and standardized module interface combination.

The industrial control all-in-one computer adopts high-quality industrial grade solid-state capacitors, which have characteristics such as anti electromagnetic interference, waterproof, dustproof, and moisture-proof, ensuring stable operation of the system.

Industrial control all-in-one computers can achieve data acquisition functions and have powerful industrial data acquisition capabilities (temperature, humidity, voltage, current, etc.). Simultaneously capable of implementing multiple interface modes (RS485/USB) and multiple communication methods.

Industrial control all-in-one computers have higher cost-effectiveness, excellent performance, and high flexibility in configuration; Adopting professional industrial grade PCB design technology and production processes ensures the stability and reliability of system operation; The product has a small volume and light weight; Support dual-mode fiber optic access/serial port access; It has rich expansion interfaces such as USB, Ethernet, etc.

What is the difference between industrial control computer and integrated industrial control computer? Industrial control computer

The main difference lies in hardware configuration. Industrial control computers use low-voltage CPU chips, which have more advantages in terms of heat dissipation conditions; Secondly, high-performance memory and hard drives are used, which have larger storage capacity compared to industrial control all-in-one computers and can better meet the needs of large-scale applications. At the same time, the industrial computer adopts an all solid state capacitor design, which not only has high reliability, long lifespan, but also lower cost; In addition, industrial computers support 2-8 hard disk partitions and have high-capacity hard disk redundancy design technology. In terms of system software, due to the lack of support from embedded operating systems, the stability and maintainability of the system may be relatively poor; Meanwhile, due to its high hardware configuration requirements, the size of industrial control computers is relatively larger. For industrial control computers, the main task is to process the information data required for industrial control and provide control instructions. According to the requirements for industrial control computers, they can be divided into the following types:

1. Industrial type

2. Specialized type

3. Universal type

4. Comprehensive type.

The most common of these types is the industrial (also known as general-purpose) industrial computer, which typically uses Intel processors or AMD processors. The difference between industrial control computers and industrial all-in-one computers

1. Visually, industrial control computers are generally installed in a standard cabinet style, with a relatively large appearance and a sturdy and durable aluminum alloy shell.

2. Motherboard: Generally designed with a 3-layer structure and using mainstream brand chips and boards.

3. Memory: Typically, it is a 16GB DDR 3X memory module (32GB or more is sufficient).

4. The size of the hard drive varies depending on the application requirements, ranging from 1TB to 6T ....