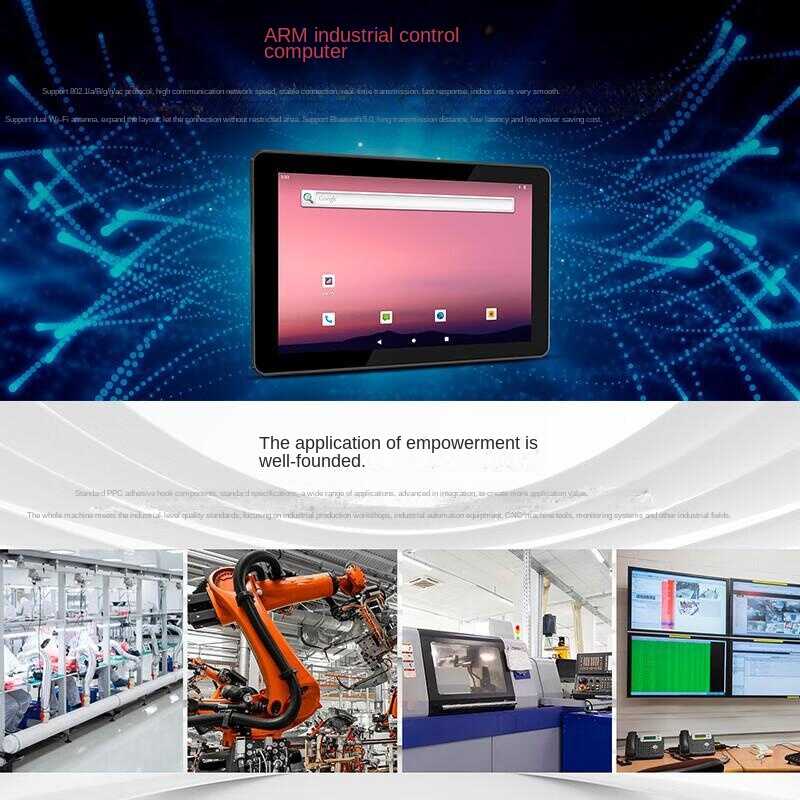

Comparison of ARM industrial control computer and PLC controller in industrial scenarios, their advantages and disadvantages

Time:2025-06-24In the field of industrial control in the past, PLC (Programmable Logic Controller) has always firmly occupied the core position of control systems with its advantages of stability, reliability, and strong anti-interference. However, with the development of society, new demands such as edge computing, artificial intelligence, data cloud, protocol conversion and so on are emerging, and ARM controller is rapidly becoming a new star in industrial control. So the question is: What are the differences between ARM controllers and traditional PLCs? Let's make a comparison between the two.

Whose 'brain' is more flexible?

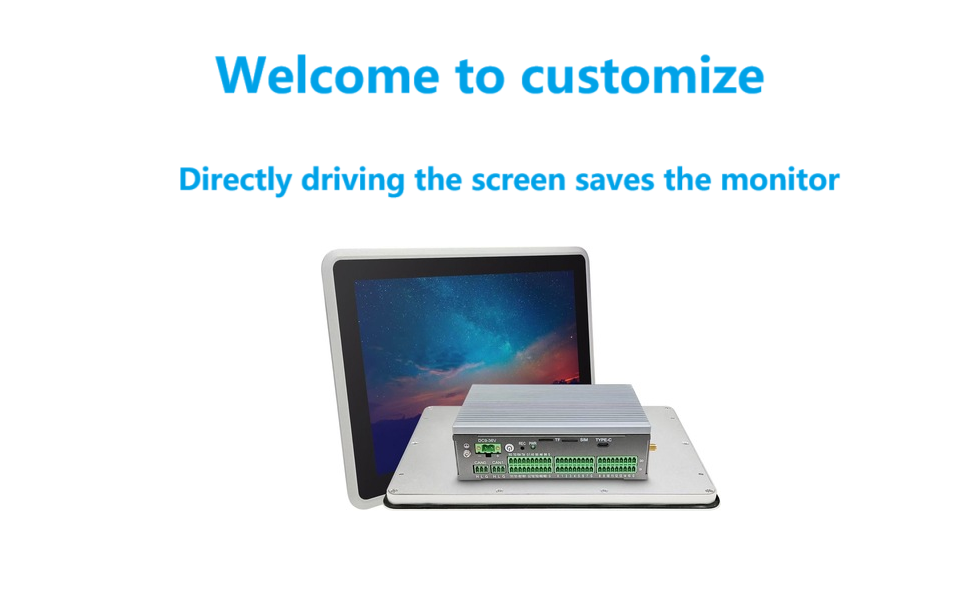

PLCs typically use dedicated industrial MCUs with a main frequency of 10 MHz to 20 MHz, which are stable enough but have limited processing capabilities. ARM controllers (such as LY-TCPCRK35) adopt high-performance architectures such as Cortex-A7 and A53, with clock speeds up to 2GHz or even higher, and support multi-core parallel computing and NPU 1TOPS computing power.

Summary: PLC is stable, ARM is smart. One is good at mechanical memory, and the other is suitable for multitasking parallel computing.

Whose communication is smoother?

PLCs usually only support industrial protocols such as Modbus and Profibus, and external gateways are required to connect to cloud platforms. ARM controllers naturally support protocols such as MQTT, OPC UA, HTTP, WebSocket, and can also have built-in Web SCADA pages for one-stop data collection and display.

Summary: ARM controllers can not only "talk" to machines, but also directly "chat" with cloud platforms.

Who is more suitable for your application?

| Application scenarios | Application scenarios |

| Single logic control, stability priority | Traditional PLC |

| Edge computing, AI recognition, data cloud | ARM controller |

| Communication protocol conversion, remote monitoring | ARM controller |

| Education, research and development, and software PLC development platform | ARM controller |

Final suggestion:

PLC will not disappear, it still plays an irreplaceable role in some key links. But the future automation scenario is no longer just about "control", but also a comprehensive capability that integrates computing, communication, collaboration, and intelligence.